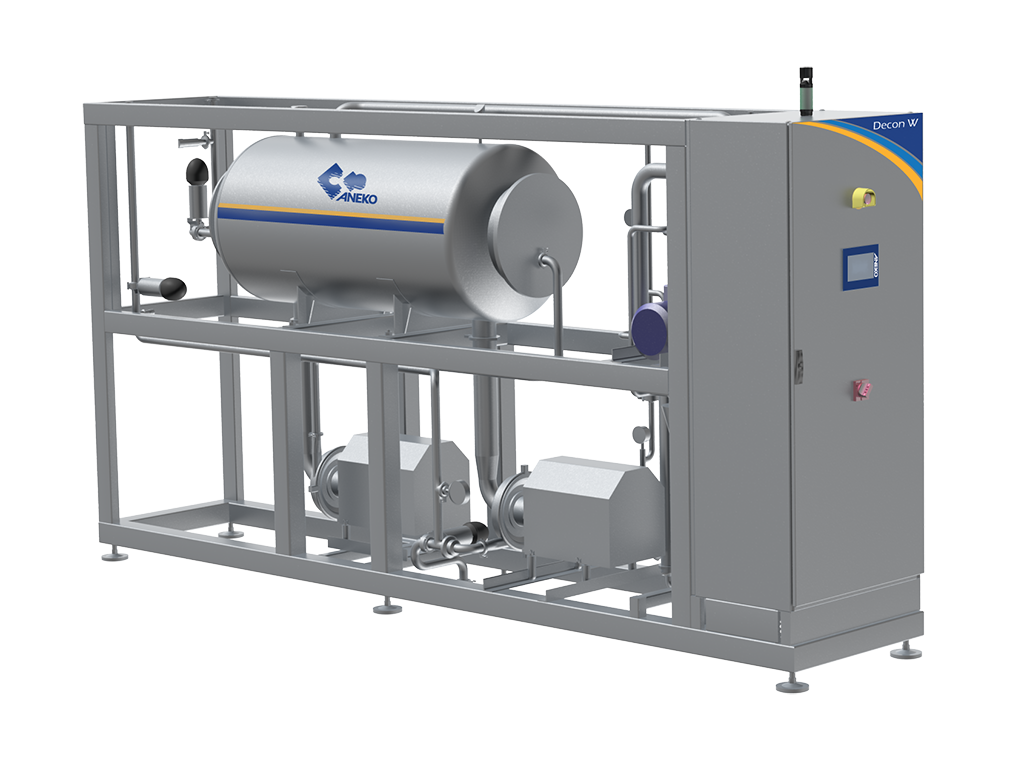

Decon-W is a continuous deaerator system that removes dissolved oxygen in water. It works by means of a vacuum pump and an atomization nozzle for the removal of dissolved oxygen in water at room temperature, achieving high levels of deaeration.

A second stage can be installed if necessary depending on the desired level of deaeration or on the content of dissolved oxygen in the incoming water.

Thought from its origin to be compatible with in-line CIP and designed to ensure a thorough cleaning.

Constant data registry, exportable, filterable by production, with the possibility to access all the records of the equipment through the ethernet network from the device that the customer defines. (Optional)

The edition of recipes is accessible by authorized operators that allows their creation and/or modification. This allows the simple creation and/or modification of recipes with flexibility. Optionally, it is possible to have a database with the extended history of the elaborations that have been carried out in the system.

The process is controlled through the touch-screen provided by the equipment as HMI, from where all the operations can be carried out in a simple and intuitive way. Decon-W has the option to replicate the screen and the operation of the equipment remotely via an installed PC in any area of the plant.