System composed of:

Please contact us at sales@aneko.com for princing and availability.

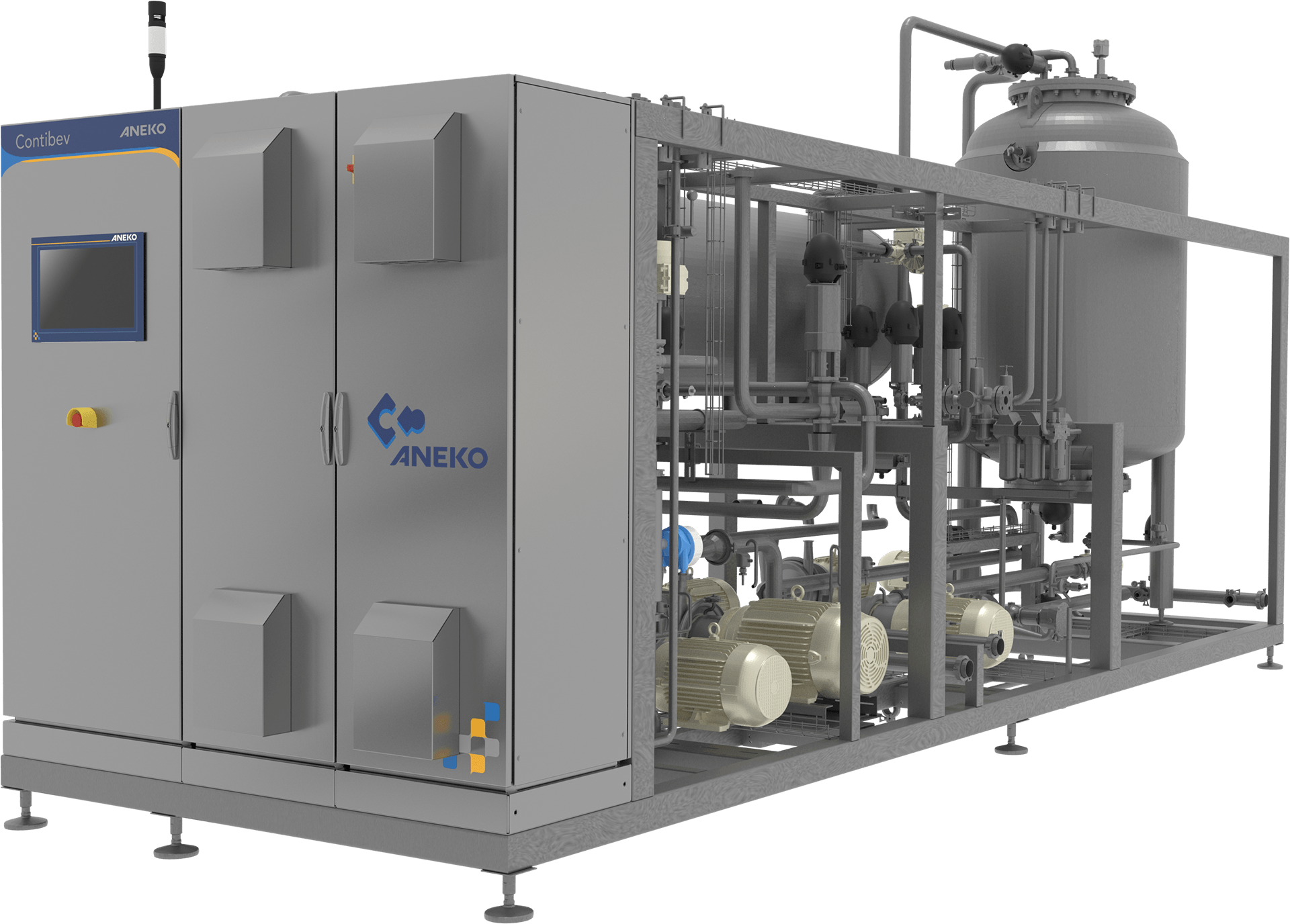

Automatic and modular equipment for final beverage elaboration. ContiBev can generate carbonated (CO2) or non-carbonated (N2) beverage, from the mixing of deaerated water and final syrup or from the intake of final beverage, allowing the equipment to be used as a carbonation system only.

This equipment combines the technologies of the Decon, ContiBlend and ContiCarb together in a single unit.

Contibev is based on mass flow rates measurements, on the final syrup dosage through pumps selected according to the product to be mixed and on the compensation through system feedback, in order to achieve a high precision on the final product, and therefore better performance.

Optionally, an automatic feedback measurement of the product output compensates the input, in order to obtain high precision during production.

The edition of recipes is accessible by authorized operators that allows their creation and/or modification. This allows the simple creation and/or modification of recipes with flexibility. Optionally, it is possible to have a database with the extended history of the elaborations that have been carried out in the system.

Losses of the Contibev are the lowest possible thanks to a CO2 flush of the components and the output line.

Thought from its origin to be compatible with in-line CIP and designed to ensure a thorough cleaning.

Compact system designed to occupy as less space as possible in your plant, allowing greater use of the available floor space.

Possibility of generating beverages from the mixture of 3 liquid veins: