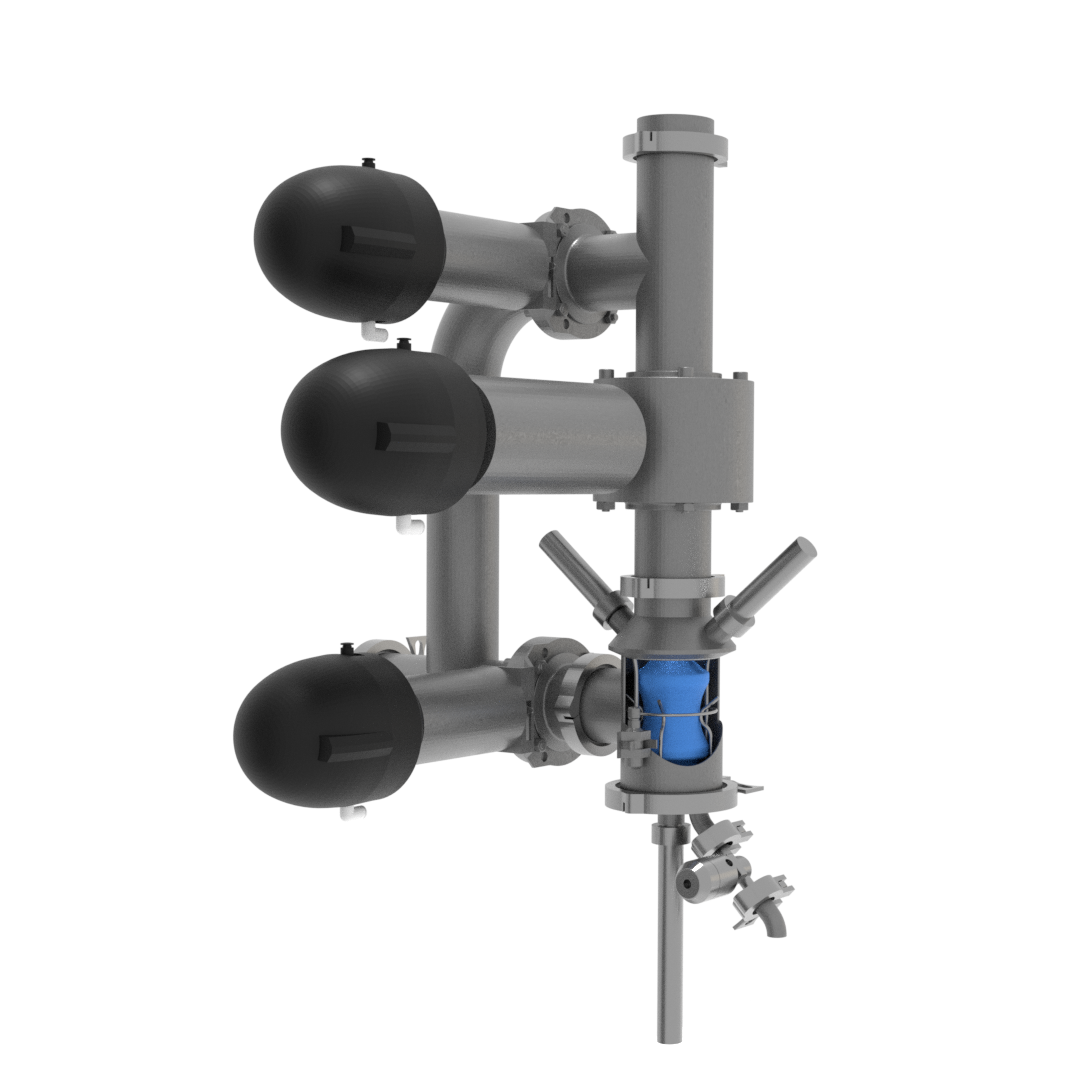

Mechanical recovery system of up to 99% of product, fully automatic, designed to be easily integrated with any processing unit.

It can be installed as an standalone version, in which case the system would have a communication with the plant to verify that the conditions are meet before use.

A sensor detects the pig position and the automation opens and closes the necessary valves for an optimum system performance. This sensor is mounted on the outside of the pipping, keeping the higienic quality of the system.

Thought from its origin to be compatible with in-line CIP and designed to ensure a thorough cleaning.

Besides the the advantage of product recovery, the system has also the advantage of easying the sanitization process of the lines, leaving almost no organic product that can complicate the effluents treatment.

When it's pushed with water, it acts as a pre-rinse before the sanitation. This represents a saving in cleaning times and in cleaning agents. It's also posible to use the pig to remove the water from the line, leaving it ready for sending final product without mixing it with water.